Building Satellites with 3D Printing? How AI + Additive Manufacturing Are Reshaping Aerospace Production Speed

China’s commercial space sector is booming, with satellite demand pushing manufacturing speed to its limits. Traditional cycles take 18–36 months per satellite, but with 3D printing and AI-driven cloud factories, the model is shifting from “years” to “months.” This article explores how AI + 3D printing + cloud manufacturing creates an agile, cost-effective path for satellite production, cutting weight by 30% and accelerating design-to-launch cycles by more than 50%.

From Drawings to Orbit: The Urgent Need for Speed

This year, Hangzhou once again entered the “space race.”

- Changguang Satellite announced its second headquarters there, targeting production of 1,000 satellites per year.

- Meanwhile, a Zhejiang University team is preparing to launch the world’s first meter-class satellite built with a fully metal 3D-printed main structure. This milestone signals a profound shift in aerospace manufacturing.

China’s commercial space market is projected to exceed 2.5 trillion RMB this year. With satellite constellations scaling rapidly, efficiency has become the new lifeline.

The critical question for manufacturers is clear:

“From blueprint to orbit, how do you beat the clock?”

The “Slow Variables” of Satellite Manufacturing

Despite booming demand, traditional satellite manufacturing cycles remain painfully slow—often 18 to 36 months per satellite. Bottlenecks arise in three major areas:

- Design and Review Inefficiency

Satellites involve thousands of parts with strict requirements for strength, thermal stability, and weight. Traditional design reviews require multiple iterations, heavy manual validation, and high communication costs. - Overly Long Process Chains

Production spans sheet metal, CNC machining, welding, heat treatment, composites, and surface finishing—often across different suppliers. Procurement cycles are long, coordination is complex, and errors multiply. - The Dual Pressure of Cost and Weight

In aerospace, every kilogram matters. Launch costs average 100,000 RMB per kg. A 500 kg satellite means a launch bill of 50 million RMB. Without effective weight reduction, both manufacturing and launch costs become unsustainable.

This lag between demand and production speed creates the core challenge:

How to move satellite production from “yearly cycles” to “monthly cycles”?

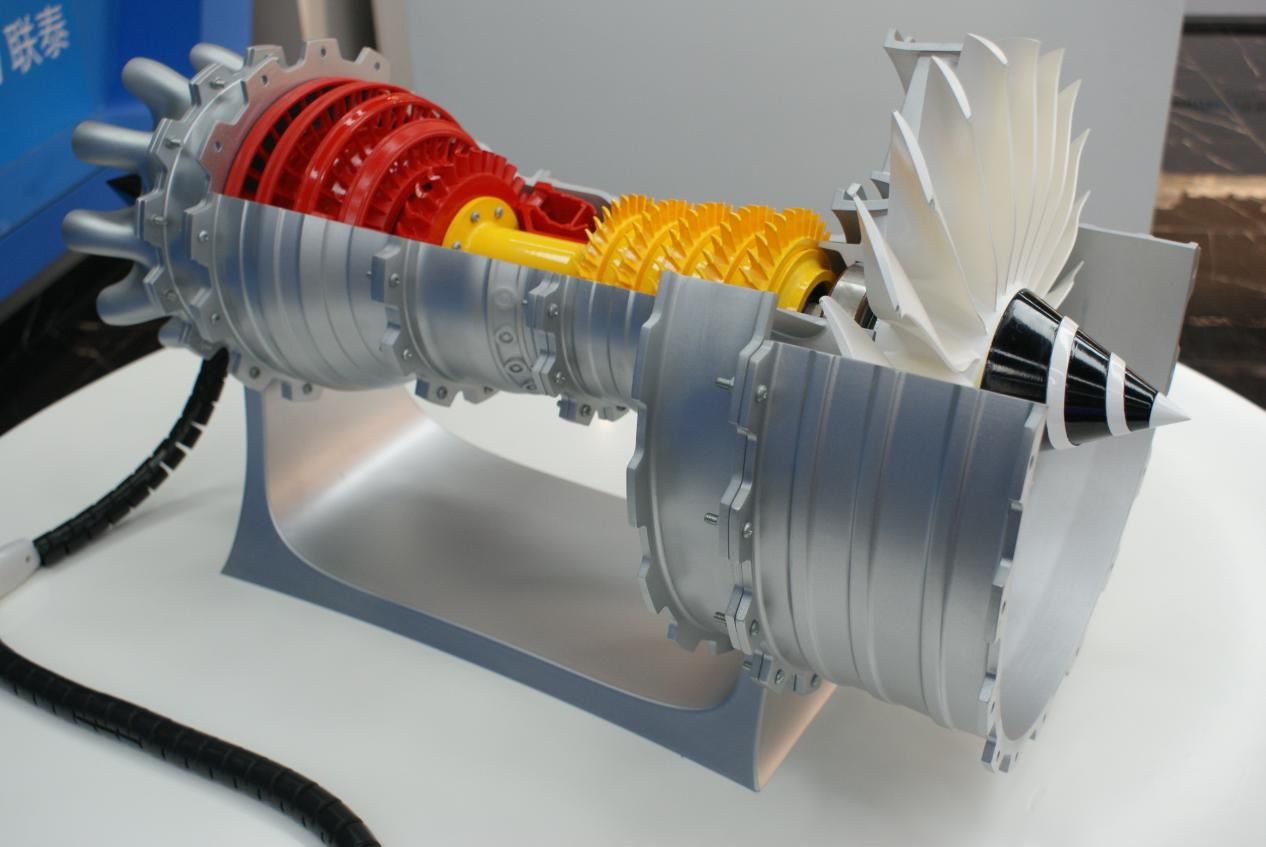

3D Printing + Lightweighting: Rewriting Satellite Manufacturing Logic

The Zhejiang University team’s satellite, with a fully metal 3D-printed structure, achieved a 30% weight reduction. That translates into millions saved in launch costs—and, more importantly, a revolution in speed.

Why 3D printing changes the game:

- Complex geometry in one build: Parts that once required multiple machining and welding steps can now be printed in one run, reducing assembly time and error rates.

- Lightweight topology optimization: Porous metal lattice structures maintain strength while cutting significant weight.

- Agile manufacturing: No need for molds; design tweaks can move to production instantly, boosting iteration speed by 50% or more.

Traditionally, satellite design refreshes were measured in years. With additive manufacturing, that pace is shifting to months—or even weeks. The Zhejiang University team’s 50 kg satellite halved its design-to-production cycle, proving 3D printing’s disruptive value to aerospace.

Why 3D Printing Alone Isn’t Enough

While additive manufacturing shortens processing time, other bottlenecks remain: design evaluation, process matching, and supply chain coordination. This is where AI + 3D printing + cloud factories come into play.

AI + 3D Printing + Cloud Factories: The Agile Manufacturing Model

To make satellites truly “fast,” the entire manufacturing chain must be restructured. AI-driven digital platforms provide exactly that:

Upload Design → AI DFM Analysis

- Automatic model inspection for thin walls, overhangs, and risk points.

- Topology optimization algorithms recommend lightweight designs while preserving structural integrity.

Real-Time AI Quoting → 99% Faster Decisions

- Traditional manual quoting takes hours or days.

- AI algorithms generate accurate cost breakdowns in ~5 seconds, covering material, process, quantity, and finishing.

- Fast quotes enable fast decisions, eliminating long inquiry loops.

Cloud Factory Collaboration → Seamless Capacity Scheduling

- Orders are automatically matched with optimal capacity across CNC, SLS, metal printing, and finishing.

- Real-time progress tracking with standardized online quality checks.

The Result: Speed + Cost Optimization

- R&D cycles accelerated by 50%+, cutting delivery times from months to weeks.

- Lightweighting significantly reduces launch costs, saving tens of thousands per kilogram.

This model gives commercial aerospace firms “national team” agility—especially in small-batch, high-variety, fast-turnaround scenarios.

The New Battleground: Speed of Smart Manufacturing

Hangzhou is quickly becoming a commercial aerospace hub:

- West Lake District is now a leading commercial space pilot zone.

- The “Satellite Supermarket” project provides one-stop access to 200+ aerospace components.

- Large-scale 3D printing facilities and Changguang’s “super factory” are under construction.

The competitive edge is shifting from “can you build” to “how fast can you build.” AI-powered intelligent manufacturing will determine which aerospace companies seize the future.

When batch-customized satellites become reality, it’s clear: the definition of speed in aerospace manufacturing must be rewritten.

Get a Free Quote!

Leave your contact details, or directly visit our online quoting platform to experience the future of material selection and production. Get expert material evaluations, tailored DFM analysis, and fast 24-hour production turnaround.

- Free Quote: Upload your designs, and our AI-powered engine will generate a custom quote in seconds.

- Talk to an Expert: Connect with one of our engineers via WhatsApp for immediate assistance.