12 Years in FDM Printing: 4 Winning Rules for Success

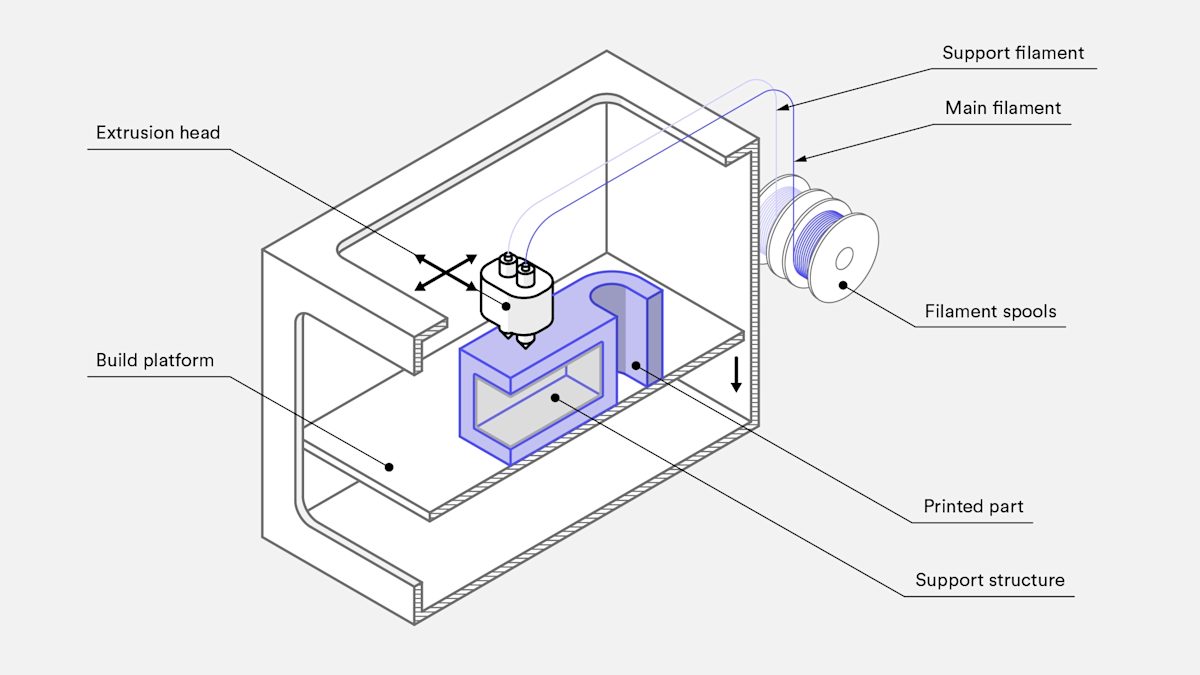

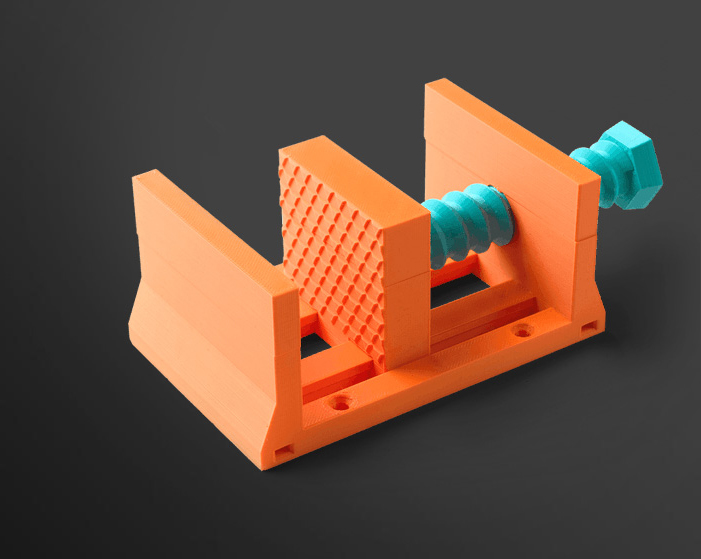

After more than a decade of working with FDM (Fused Deposition Modeling) technology, I’ve found that whether the goal is rapid prototyping or small-batch production, output quality ultimately depends on four critical factors: design precision, structural optimization, smart use of supports and print orientation, and the seamless integration of materials with process parameters.

In this article, I’ll break down these four dimensions in depth and share how you can leverage the Leanplans platform to achieve high-strength, cost-efficient FDM printed parts—right from the first build.

1. Precision in Design: From Wall Thickness to Fine Features

In the world of FDM printing, design is the foundation—it determines the success or failure of every step that follows. Over the years, I’ve debugged hundreds of models, and the most common mistakes are misjudgments in wall thickness and tiny features.

Take a standard 0.4 mm nozzle as an example: three times the nozzle diameter (~1.2 mm) is the “sweet spot” balancing strength and material efficiency. Wall thickness below 0.8 mm often leads to warping and poor layer adhesion, while going beyond 2 mm dramatically increases print time and risks delamination or cracking due to internal stress.

For load-bearing parts, I recommend using finite element analysis (FEA) to reinforce localized stress zones rather than thickening the entire model. Cross-hatch infill at 20–30% density is another cost-saving trick—sufficient for non-critical areas while cutting down material and print time.

Seemingly small details such as pins, bosses, and embossed text often become weak points. Pins under 2 mm in diameter tend to snap during post-processing or assembly, so I always keep diameters ≥2 mm. Likewise, embossed text thinner than 0.8 mm or shorter than 1.5 mm looks crisp on-screen but fails in reality. In practice, I slightly oversize these features in CAD, then select high-precision mode on the Leanplans platform to ensure clean results without extra finishing.

2. Structural Optimization: Controlling Overhangs and Preventing Warping

Because FDM is a layer-by-layer process, it enables complex geometries but is also prone to issues with overhangs and large flat surfaces. Overhangs greater than 45° often sag or leave stringy residue. Instead of relying heavily on supports, it’s smarter to integrate gentle slopes or chamfers in the design, giving each layer a proper foundation. For bridges over 5 mm, I usually raise the ends slightly (0.2–0.5 mm) and add tiny pillars to reduce drooping.

Warping, on the other hand, stems from uneven cooling and large planar areas. A flat part sized 120 × 120 mm often curls at the edges during the first layer. My go-to strategy: split large planes into smaller modules with rounded edges, or add a 3–5 mm brim or skirt to improve adhesion. With shrink-prone materials like ABS, I design rib-like “fences” around edges to disperse stress from thermal contraction.

This “modularization + reinforcement + adhesion” approach keeps even 200 × 200 mm flat parts warp-free, significantly improving first-pass yield.

3. Smart Supports and Print Orientation: Less Is More

Supports are both a savior and a nuisance in FDM printing. Leanplans offers tree supports and dissolvable supports, which preserve structural reliability while minimizing post-processing headaches. Before finalizing a build, I experiment with multiple orientations in slicing software to identify a minimal-support setup. Often, a simple 10° rotation reduces support needs by 20% or more.

Print orientation matters as much as support:

Print orientation matters as much as support:

- Layer adhesion is weakest along the Z-axis, at only ~60–70% of XY strength. Place tension- or bending-critical features parallel to the print bed.

- Surface smoothness improves when curves and slopes are aligned parallel to the build plate.

- Holes look cleaner when oriented along Z, reducing the need for supports.

This three-step approach—rotate, minimize supports, set orientation—produces cleaner parts, reduces post-processing, and boosts strength where it counts.

4. Materials and Process: The Final Step to Reliable Prints

Even the best design will fail if the process parameters are off. Poor temperature control causes stringing, delamination, or nozzle clogs. To solve this, Leanplans’ AI multi-agent system automatically matches nozzle temperature, print speed, and fan settings based on model geometry and material choice:

- PLA: 200–210 °C nozzle, 50–60 °C bed

- PETG: 230–240 °C nozzle, 70–80 °C bed

- ABS: ≥100 °C heated bed + enclosed chamber for stable bonding

For materials, PLA and PETG are “low-warp” favorites, while nylon or carbon fiber composites deliver higher strength and thermal resistance. Leanplans provides a full range of engineering-grade filaments and recommends material-process pairings tailored to your part’s function. With high-precision sensors and real-time camera monitoring, the system halts or alerts if deviations occur—ensuring every part meets design intent.

Conclusion: The Complete FDM Success Formula

These four rules—precision design, structural optimization, smart support and orientation, and material-process synergy—form a closed loop for FDM success. On the Leanplans online platform, you simply upload your CAD file, and the system takes care of instant quoting, optimized slicing, production scheduling, and quality tracking. With the combination of AI and over a decade of practical know-how, your designs are transformed into high-strength, cost-efficient printed parts, without the common pitfalls.

In your next project, apply these principles to achieve a perfect balance of efficiency, durability, and cost-effectiveness—and let Leanplans help you get it right the first time.

Get a Free Quote!

Leave your contact details, or directly visit our online quoting platform to experience the future of material selection and production. Get expert material evaluations, tailored DFM analysis, and fast 24-hour production turnaround.

- Free Quote: Upload your designs, and our AI-powered engine will generate a custom quote in seconds.

- Talk to an Expert: Connect with one of our engineers via WhatsApp for immediate assistance.